Machining

Manufacturing of parts through machining processes

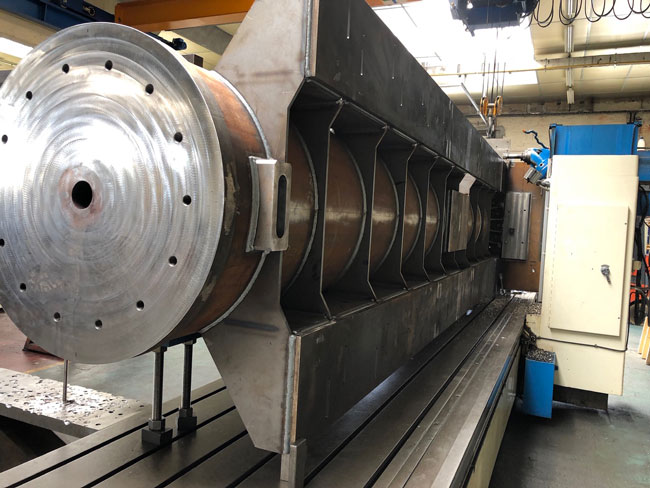

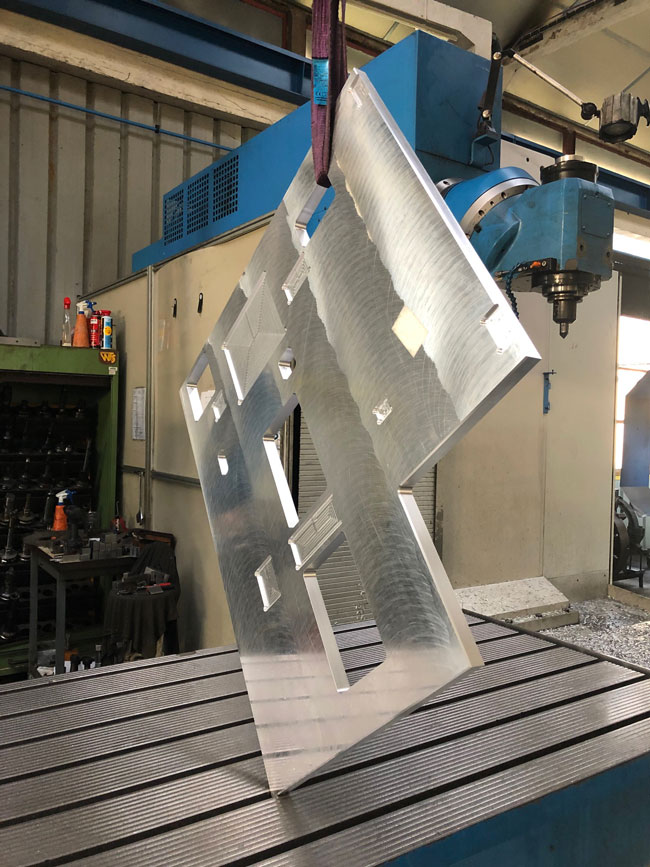

The machining activity encompasses numerous skills within MASTERMECA: boring, milling, turning, drilling, threading, tapping, knurling, mortising, cutting.

MASTERMECA manufactures and machines complex single parts and small series for all sectors of activity:

- Tooling production

- Maintenance parts

- Specific parts

- Cast parts

- Mechanically welded frames

- Large parts (maximum weight 5 tons)

- Small parts

Parts or assemblies for:

- Defense

- Aerospace

- Automotive

- Railways

- Metallurgy

- Nuclear

- Robotics

- Pharmaceutical Laboratories

- Cosmetics

- Food Industry

- Special Machinery

Specific Skills

- Conventional machining

- CNC machining

- CAD/CAM

- Large capacity machining

- Machining to specification

- Machining according to model and technical specifications

- Prototypes

- Small and medium series

- Special machines

- Mechanically welded assemblies

MASTERMECA places great importance on the selection of its suppliers and the quality of its raw materials.

Assembly

MASTERMÉCA has its own assembly workshop. All parts and tools are delivered assembled. MASTERMÉCA supplies the commercial components (screws and accessories) required for assembly.

Polymer additive manufacturing

Prototyping and Production

Advantages of 3D printing

- Customisation of parts

- Manufacture parts with complex shapes

- Optimisation of raw material consumption

- Cost reduction

Personalised support for your projects

- Design of your parts

- Production of an STL file from your 3D CAD file

- Post-processing and finishing